1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

-

Pn25 Full Bore Locked Bronze Ball Valve With Cutting Ferrule

Item No.: 61208024

View detailsΦ20 Φ25 Φ32 Φ40 Φ50 Φ63

-

Bronze Ball Valve With Cutting Ferrule + F Thread + Graphite Gasket

Item No.:

View details1/2" ×Φ20 3/4" ×Φ25 1" ×Φ32 1-1/4" ×Φ40 1-1/2" ×Φ50 2" ×Φ63

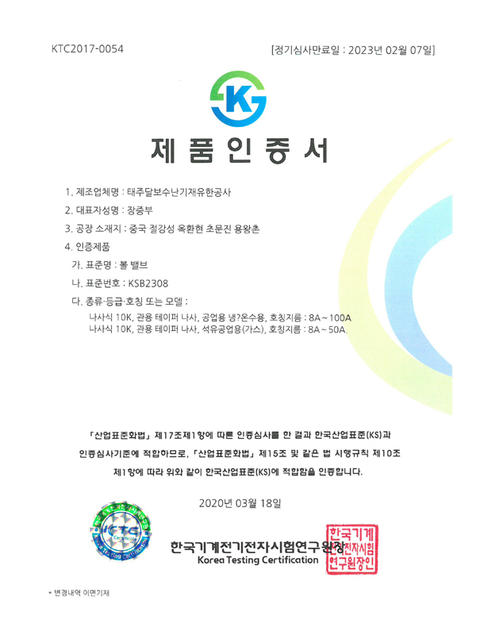

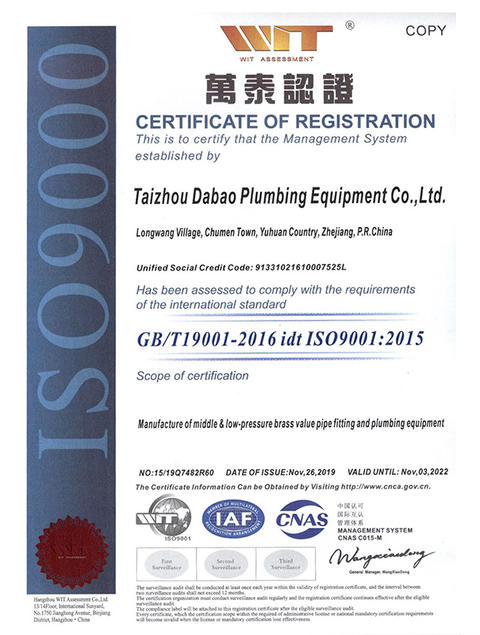

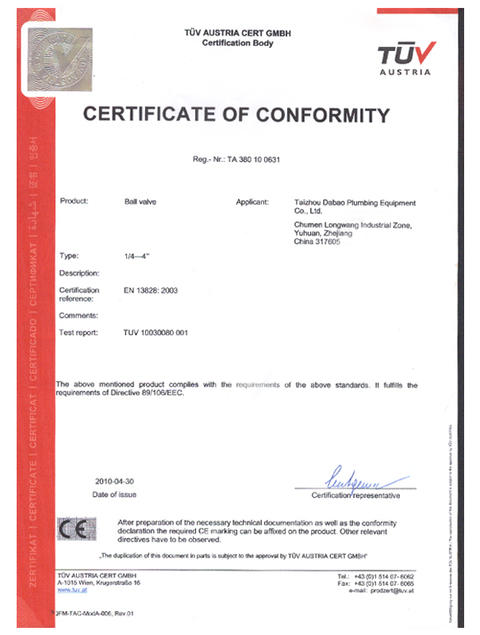

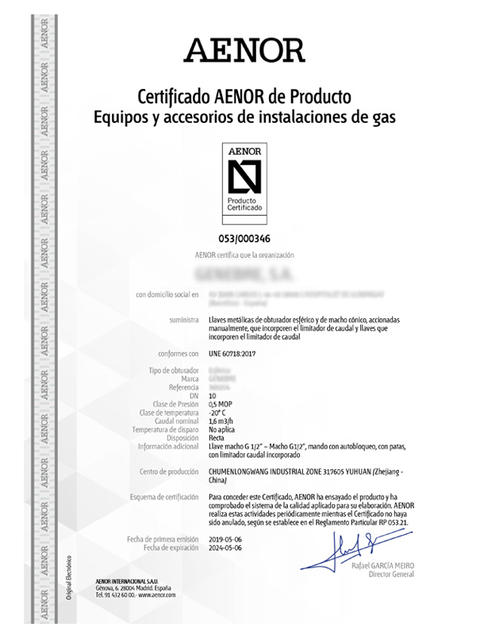

Full Bore Bronze Ball Valve Manufacturers

Product Series

Contact Us

Feel Like Talking

+ 86-576-89902377

+ 86-576-89902379

Contact Email

tdb@tdbvalve.com

Address

Chumen LongWang Industrial Zone, Yuhuan City, Zhejiang, China, 317605

Taizhou Dabao

Plumbing Equipment Co.,Ltd.

News & Media

Continuous Improvement, Great Products and Service Lead to Long Term Partnership.

-

Innovations In China PN25 Ball Valve: What You Need To Know

Design High Quality China Butterfly PN25 Ball Valve Supplier Company In recent years, the China PN25 ball valve has garnered significant attention for its advan

+ View more -

Understanding Quality Standards For China PN25 Ball Valve

ODM Custom China Butterfly PN25 Ball Valve Exporter Producer In the realm of industrial valves, the China PN25 ball valve has gained significant attention for i

+ View more -

The Evolution And Performance Of China PN25 Ball Valve Technology

OEM China Butterfly PN25 Ball Valve Manufacturing Wholesaler The China PN25 ball valve has become a cornerstone in the global industrial sector due to its robus

+ View more -

Exploring The Features And Applications Of China PN25 Ball Valve

Sale Wholesale China Butterfly PN25 Ball Valve Factory Manufacturer The China PN25 ball valve is a crucial component in various industrial applications, renowne

+ View more

English

English 한국어

한국어 Español

Español 中文简体

中文简体