3/8" 1/2" 3/4" 1"

Brass Fittings Manufacturers

Product Series

Contact Us

Feel Like Talking

+ 86-576-89902377

+ 86-576-89902379

Contact Email

tdb@tdbvalve.com

Address

Chumen LongWang Industrial Zone, Yuhuan City, Zhejiang, China, 317605

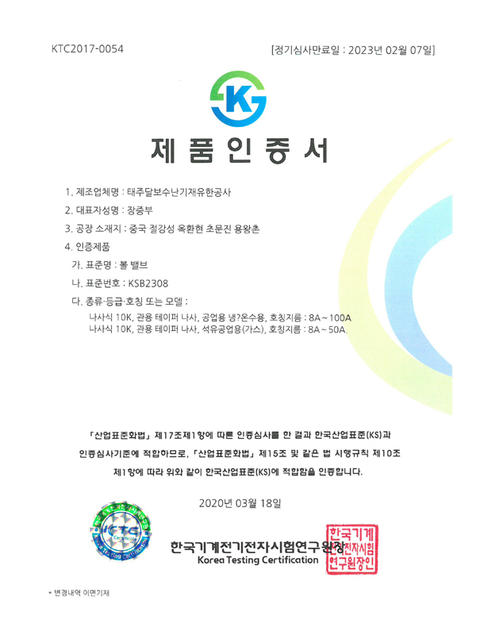

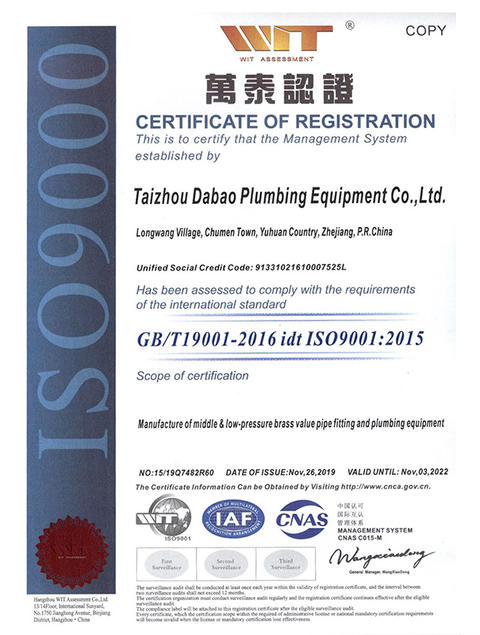

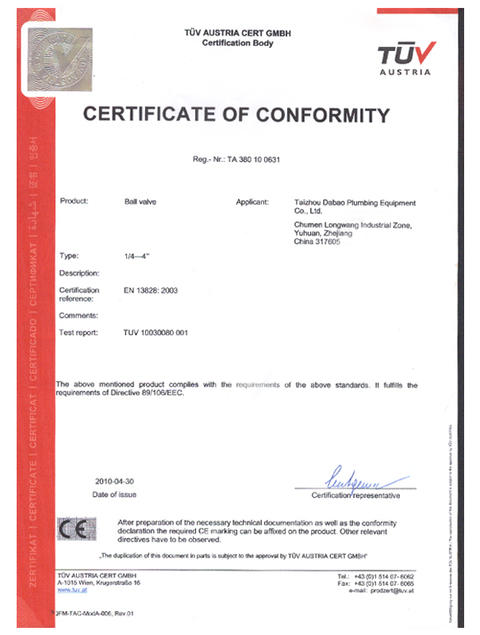

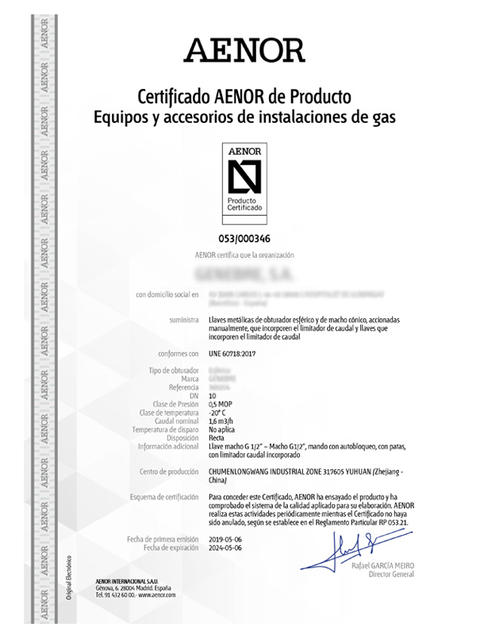

Taizhou Dabao

Plumbing Equipment Co.,Ltd.

News & Media

Continuous Improvement, Great Products and Service Lead to Long Term Partnership.

-

Reliable Wholesale Brass Ball Valves: Ensuring Quality And Affordability

Custom Design Wholesale Gas Stove Brass Valve Valves Manufacturing In the realm of plumbing and industrial applications, the importance of reliable wholesale br

+ View more -

Premium Wholesale Brass Ball Valves: A Bulk Solution For Quality And Affordability

OEM ODM Wholesale Gas Stove Brass Valve Valves Manufacturer In today's industrial landscape, the demand for reliable plumbing and fluid control solutions has ne

+ View more -

Ensuring Quality: Exploring The Benefits Of Wholesale Brass Ball Valves

Sale China Wholesale Gas Stove Brass Valve Valves Factory In the realm of plumbing and industrial applications, the significance of brass ball valves cannot be

+ View more -

Meeting Industry Standards: The Commitment Of Brass Gas Valve Manufacturers

Design High Quality Brass Gas Valve For Gas Manufacturers Maker Brass gas valves are essential components in gas supply systems, providing control and regulatio

+ View more

English

English 한국어

한국어 Español

Español 中文简体

中文简体